- 半导体首页

-

应用车载工业设备消费类/个人设备

-

产品车载器件

分立半导体

二极管

晶体管

通用逻辑IC

模拟器件

※

: 产品列表(参数搜索)

功率半导体※

: 产品列表(参数搜索)

隔离器/固态继电器※

: 产品列表(参数搜索)

MOSFETIGBT/IEGT双极晶体管二极管※

: 产品列表(参数搜索)

微控制器电机驱动IC- 直流无刷电机驱动IC

- 直流有刷电机驱动IC

- 步进电机驱动IC

智能功率IC※

:产品列表(参数搜索)

电源管理IC线性IC※

: 产品列表(参数搜索)

通用逻辑IC线性图像传感器其他产品用IC其他产品用IC

※

: 产品列表(参数搜索)

-

设计与开发

-

知识库

- 购买

- 型号 & 关键词搜索

- 交叉搜索

- 参数搜索

- 库存查询与购买

This webpage doesn't work with Internet Explorer. Please use the latest version of Google Chrome, Microsoft Edge, Mozilla Firefox or Safari.

请输入3个以上字符 Search for multiple part numbers fromhere.

The information presented in this cross reference is based on TOSHIBA's selection criteria and should be treated as a suggestion only. Please carefully review the latest versions of all relevant information on the TOSHIBA products, including without limitation data sheets and validate all operating parameters of the TOSHIBA products to ensure that the suggested TOSHIBA products are truly compatible with your design and application.Please note that this cross reference is based on TOSHIBA's estimate of compatibility with other manufacturers' products, based on other manufacturers' published data, at the time the data was collected.TOSHIBA is not responsible for any incorrect or incomplete information. Information is subject to change at any time without notice.

请输入3个以上字符

步进电机驱动IC

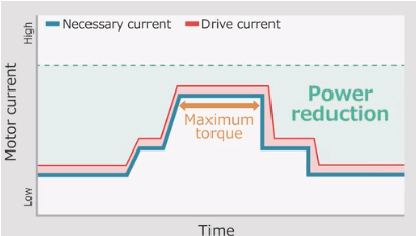

机电产品的机械子系统采用多个步进电机,它们需要消耗过大的电流以防失步,从而产生大量的热量。

主动增益控制(AGC)采用一种简单的技术来解决这一问题,提高了产品的价值。

产品线

产品线

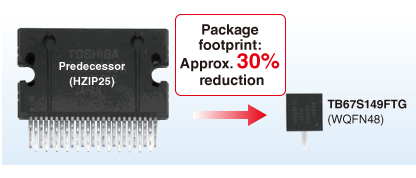

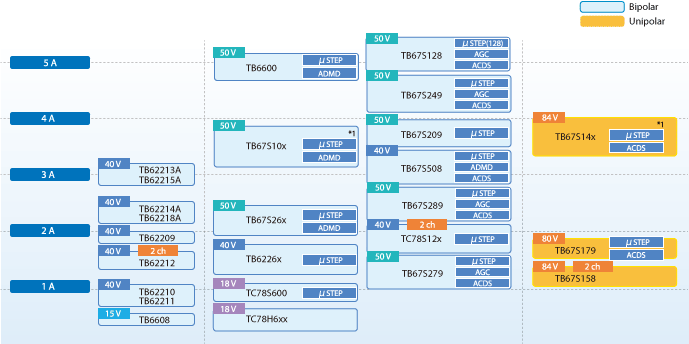

东芝提供采用BiCD工艺制造而成的丰富的步进电机驱动IC产品系列,能提供高精确度和大电流能力。东芝的步进电机驱动IC提供双极和单极结构。

*1 TB67S105和TB67S145不支持微步进。

参数搜索

步进电机驱动IC 产品线

交叉搜索

请输入3个以上字符

About information presented in this cross reference

The information presented in this cross reference is based on TOSHIBA's selection criteria and should be treated as a suggestion only. Please carefully review the latest versions of all relevant information on the TOSHIBA products, including without limitation data sheets and validate all operating parameters of the TOSHIBA products to ensure that the suggested TOSHIBA products are truly compatible with your design and application.Please note that this cross reference is based on TOSHIBA's estimate of compatibility with other manufacturers' products, based on other manufacturers' published data, at the time the data was collected.TOSHIBA is not responsible for any incorrect or incomplete information. Information is subject to change at any time without notice.

技术专辑

技术介绍视频

产品介绍视频

东芝原创技术

东芝步进电机驱动IC的特点

丰富的产品线

用于解决客户需求和问题的基于先进技术的解决方案

异常检测技术

内置异常检测电路,例如低压(UVLO)、过流(ISD)和过热(TSD)。

有助于构建高度可靠的系统。 (注:内置的错误检测功能因产品而异。)

仿真器

下载PSpice®模型

购买、样品、及IC可靠性查询

库存查询与购买

请输入3个以上字符

Through this website you are able to proceed to the website of our distributors ("Third Party Website") which is not under the control of Toshiba Corporation and its subsidiaries and affiliates (collectively "Toshiba"). The Third Party Website is made available to you as a convenience only and you agree to use the Third Party Website at your own risk. The link of the Third Party Website does not necessarily imply a recommendation or an endorsement by Toshiba of the Third Party Website. Please be aware that Toshiba is not responsible for any transaction done through the Third Party Website, and such transactions shall be subject to terms and conditions which may be provided in the Third Party Website.

相关信息

* PSpice®是Cadence Design Systems, Inc.的注册商标。

* 本文提及的公司名称、产品名称和服务名称可能是其各自公司的商标。