What are the advantages of using eFuse ICs over glass fuses and polyswitches?

eFuse IC (electronic fuse) can cut off current like a glass tube fuse (chip fuse) and can also be restarted without replacing like a polyswitch (PTC thermistor, polyfuse, resettable fuse). Glass tube fuses, polyswitches, etc. are cut off (or suppressed) by the heat generated (temperature rise) caused by overcurrent. Unlike this, eFuse IC directly monitors and judges the current (voltage), allowing for highly accurate shutoff in a short time. In addition, eFuse IC has a variety of protection functions such as thermal shutdown, over voltage clamp, and reverse current blocking, making it possible to achieve high system reliability.

Major features:

Glass tube fuses, polyswitches, and eFuse ICs are both used for overcurrent protection. The difference between these two is the state when overcurrent flows and whether or not replacement is necessary.

Condition when overcurrent flows

- Cuts off the current:

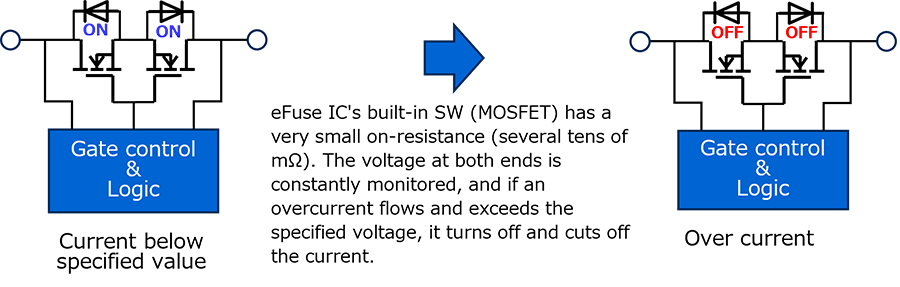

The internal fuse element (metal wiring) of a glass tube fuse melts and opens the circuit. The eFuse IC turns off the built-in switch (MOSFET) to cut off the current. - Limit the current:

As the temperature of PolySwitch increases and it reaches a certain temperature, the series resistance value increases exponentially. This increase in resistance reduces the current.

Necessity of replacement?

- Replacement required:

When a glass tube fuse operates, the internal wiring is blown and cannot be restored. - No need to replace:

When the temperature of the polyswitch element decreases, the series resistance value decreases and the element returns to its original state. eFuse IC can easily return to its original state by turning on the built-in switch.

With eFuse ICs, there are two ways to return to the original state after cutting off the current, depending on the IC selected.

1) Auto-retry type: Performs recovery operation after a certain period of time (approximately 100 usec).

2) Latch type: Reset using an external control signal (signal to the EN/UVLO terminal).

Auto-retry type and latch type have advantages and disadvantages.

With plug-and-play devices such as audio equipment, monitors, mice, and keyboards that are connected to PCs and smartphones, there may be abnormal connections such as broken cables, poor connections in connectors, or connection of malfunctioning devices. This may cause an overcurrent to flow and activate the current control element described above.

(Please also refer to the FAQ below.)

Can eFuse IC (electronic fuse) be used for hot-swap?

In such cases, a resettable element (an auto-retry type element) such as a polyswitch that does not need to be replaced after the failure is cleared is required. However, in the case of polyswitches, the suppressed current continues to flow. Also, if the cause of overcurrent is not removed, the temperature rise ←→ temperature drop will repeat.

When equipment requires reliability or downstream safety is important, it is important to stop the current and recover from the fault before operating the equipment. For such applications, a device such as a glass tube fuse that completely cuts off the current and operates only after confirmation is ideal.

The eFuse IC can respond to either resettable (auto-retry type) or complete stop (latch type that restarts with a control signal) requirements by selecting the IC.

Operating principles of glass tube fuses, polyswitches, and eFuse ICs:

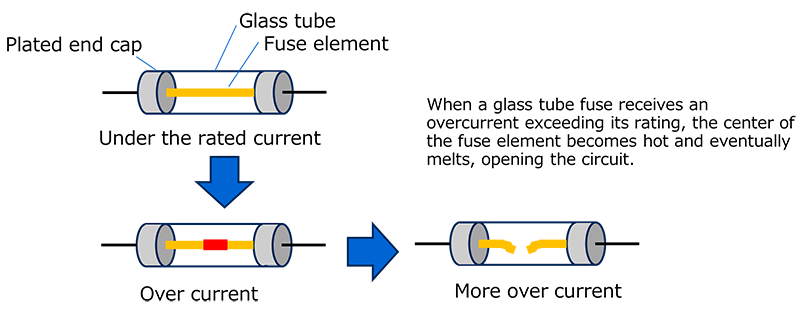

Glass tube fuses cut off the current by causing the temperature of the fuse element to exceed its melting point and melt due to the Joule heat generated by the current passing through the fuse and the resistance of the fuse.

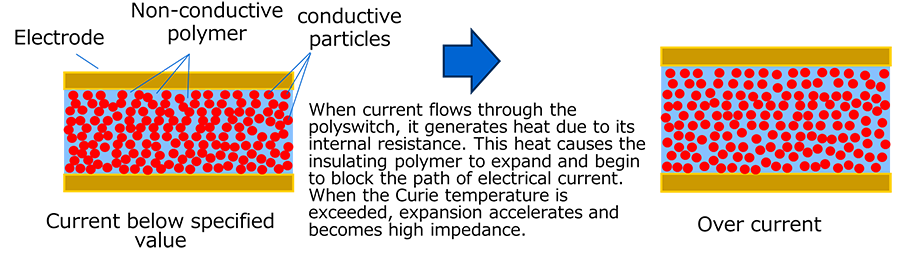

There are two types of polyswitches: polymer PTC and ceramic PTC. Polymer PTC is used to prevent overcurrent. Polymer PTC is made by mixing conductive particles (metals such as carbon and nickel) with an insulating polymer.

At room temperature, the conductive particles are in contact with each other, creating a low-resistance element. During overcurrent, the Joule heat generated by the current passing through the thermistor and the resistance of the thermistor causes the thermistor's polymer to expand and the conductive elements to separate, resulting in high resistance. The resistance value increases rapidly when it exceeds the Curie temperature (the temperature at which the resistance value is twice the resistance value at 25 °C).

Glass tube fuses and PTC thermistors both utilize the rise in temperature of the element due to Joule heat generated by increased current. Therefore, it takes some time for it to work. Also, the ambient temperature, which is the initial temperature, has an effect. Furthermore, PTC thermistors are greatly affected by thermal resistance (mounting condition with the board, board pattern, etc.) that affects temperature rise.

On the other hand, eFuse IC monitors the voltage across the built-in switch, determines the passing current value, and turns off the switch (MOSFET), so it takes almost no time to operate. It is less affected by ambient temperature, etc., and can be cut off at an accurate current value.

Related Links

The following documents also contain related information:

FAQs

Application Notes

* Company names, product names, and service names used in this FAQ may be of their respective companies.